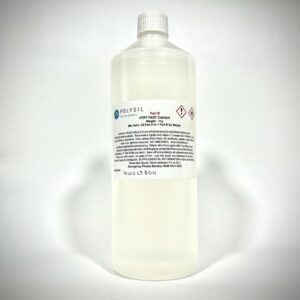

Economy Silicone Rubber Base (catalyst needed)

RTV Silicone Rubber for Jesmonite, polyurethane/polyester/epoxy resin, unsaturated resin, plaster, candles and gypsum crafts, toys, soaps, statues, casting, mould making and more….

£10.00 - £280.00

Next Working Day Delivery

Next Working Day Service via DHL or Parcelforce 24 Tracked. Please be aware we are not liable for any delays or delivery problems with these third party Carriers ( see "Shipping and Returns" in footer).

Shipping Information

Our shipping costs are worked out by the gross weight of your order delivered to your address. NB: We do not currently ship internationally (UK only).

RTV silicone rubber for Jesmonite, polyurethane/polyester/epoxy resin, unsaturated resin, plaster, candles and gypsum crafts, toys, soaps, statues, casting, mould making and more….

Features:

- Two part silicone rubber kit: liquid silicone base. (curing agent available separately).

- Easy 20:1 by weight mix ratio

- Exceptional fluidity, easy to mix, easy to de-mould.

- Good tensile and tear strength, very low shrinkage…

RTV Economy Silicone Rubber Kit – Technical Guidelines:

- Shake the catalyst container well before use.

- Weigh the desired amount of base into a clean mixing container.

- Weigh the proper amount of catalyst into the container. Mix the base and catalyst together by stirring with a stick until a uniform colour is obtained. Scrape the container walls and bottom well to insure a thorough mix.

- Though it is often unnecessary to de-air the material due to its low viscosity, some may choose to do so. If so, place the container into a vacuum chamber and extract the air from the mixture using a vacuum pump capable of achieving 29 inches of mercury vacuum. The mixture will rise, crest and then collapse in the container. Interruption (bumping) of the container may be necessary to prevent the container from overflowing. Keep the mixture under full vacuum for 2 – 3 minutes.

- Slowly bleed air into the vacuum chamber. When the chamber is at atmospheric equilibrium, remove the cover plate and take out the container.

- Pour the de-aired material slowly in a steady stream from one end of the mould so that the material flows evenly over the pattern. This should minimise the entrapment of air bubbles under the flowing material.

A mould release agent may be applied on the pattern first, to improve release.

- Allow the rubber to cure before removing the cured rubber mould from the pattern. Heat acceleration is not recommended with this product.

- For the best results, allow the mould to air cure for an additional 24 hours before using it in production.

RTV Silicone Rubber – Shelf life:

12 months from date of shipment when stored at 25°C in the original sealed packages.

RTV Silicone Rubber – Notes:

Silicone rubber is greatly affected by temperature. The above testing data is purely for reference purposes, specific use is down to the user’s discretion. Before large scale application, it is recommended to take a small amount for testing purposes first. Once you are satisfied with the results, large scale production can begin. Polysil Ltd cannot be held liable for losses as a result of the above not being followed.